Products

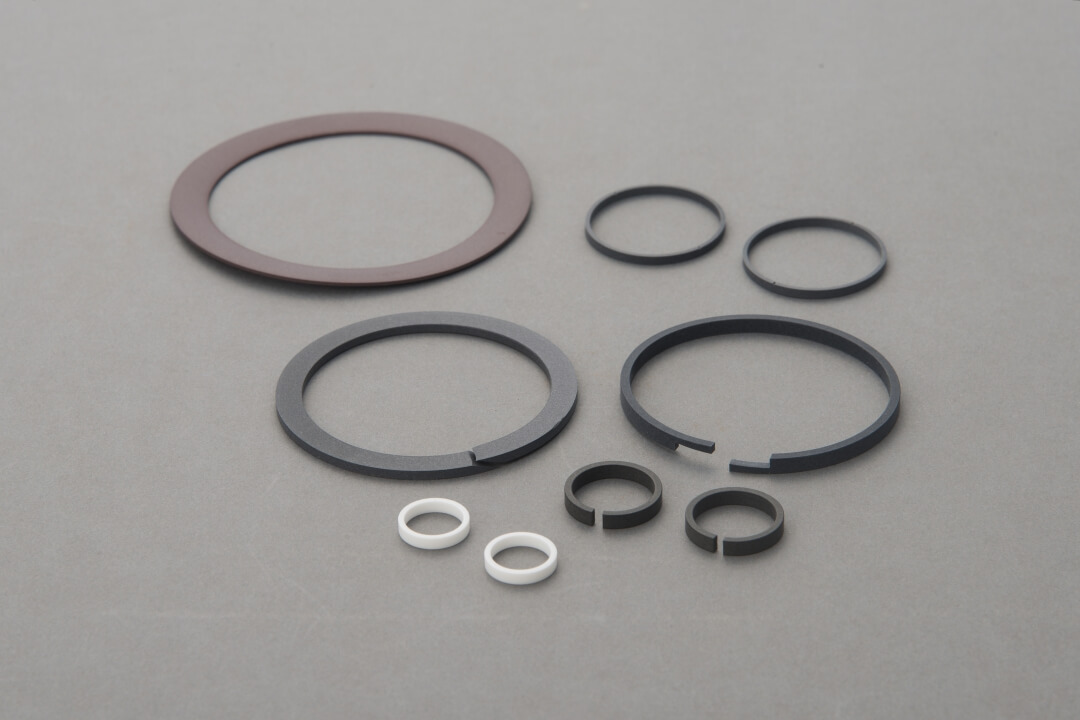

Filled PTFE material/compression molded product

- Products

- PTFE processing materials

overview

By adding fillers, this compression molded product has heat resistance and chemical resistance that are the characteristics of fluoroplastic (PTFE), as well as wear resistance, creep resistance, and mechanical characteristics. We not only process various PTFE parts, but also provide an integrated production process from material molding to the dimensions of the processed parts.

Cutting processing is also possible.

Applications

・Packing and gaskets

・Valve seats

Bellows

・Ball seat

·piston ring

・Bearings etc.

Operating temperature limit

-60°C to +260°C

Features

●Excellent non-stick characteristics, chemical resistance, electric insulation, low friction, and heat resistance.

By using fillers, the above features can be enhanced with wear resistance, creep resistance, and mechanical characteristics.

Types and grades of PTFE compression molded products

Types of PTFE compression molded products

| name | Commentary | Applications |

|---|---|---|

| virgin | It is a representative material that has excellent chemical resistance, abrasion resistance, and heat resistance when used as a sealing material or individual part. | Packings, gaskets, valve seats, etc. |

| Denatured type | This is a new type of PTFE that has excellent creep resistance, flex life, and tensile strength, making it suitable for dynamic sealing materials. | Gaskets, valve seats, bearing pads etc. |

| Glass fiber (filler) | It has little effect on the chemical and electrical properties and greatly improves mechanical characteristics and abrasion resistance, but has the disadvantage of causing wear to the mating material. | Bearings, gaskets, valve discs etc. |

| Graphite (filler) | It has improved cold flow resistance, low initial wear and starting resistance, good thermal conductivity, and excellent chemical resistance, making it particularly suitable for chemical applications. | Gaskets, packings, etc. |

| Bronze (filler) | It has improved abrasion resistance, strength, and compressive strength. Because it is a metal filler, it has good thermal conductivity, but chemical resistance is reduced. | Bridge bearings, gate bearings, piston rings, etc. |

| Carbon fiber (filler) | It has excellent compressive strength and creep properties. Creep properties in particular are significantly improved at high temperatures of over 200 degrees. It also has excellent abrasion resistance and good abrasion properties in water. | Bearings, mechanical seals, bearing pads, piston rings, etc. |

| Molybdenum disulfide (filler) | It is rarely used alone as a filler, but is generally used together with glass fiber or bronze, etc., and adding a small amount can improve hardness, tensile strength, abrasion resistance and electric insulation. | Piston rings, tape liner bearings, etc. |

| Econol (filler) | Suitable for bearings of soft metal materials. Also suitable for use underwater. | Bearings, piston rings, etc. |

grade

| virgin | Denatured type | Glass 15% | Glass 20% | Glass 25% | Glass 25% Molybdenum 5% |

Glass 20% Graphite 5% |

|---|---|---|---|---|---|---|

| Carbon 10% | Carbon 15% | Carbon 25% | Graphite 15% |

carbon Graphite twenty five% |

Bronze 60% | Econol 20% |

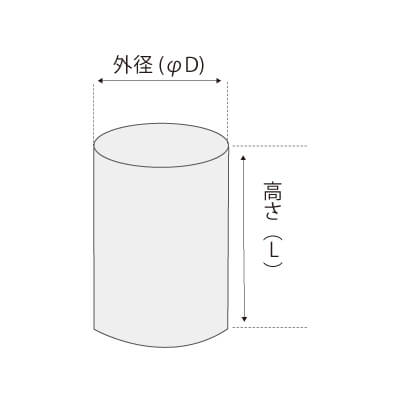

*1 Height can be adjusted from a minimum of 50mm to a maximum of 150mm (however, for heights of 101mm or more, the wall thickness must be 10mm or more).

*2 We also stock special sizes and shapes (square, ball, etc.) other than those listed above. Please contact us for details.

Compression Molding Product Size Chart

■ PTFE Rod

|

|

|||||||||||||||||||||

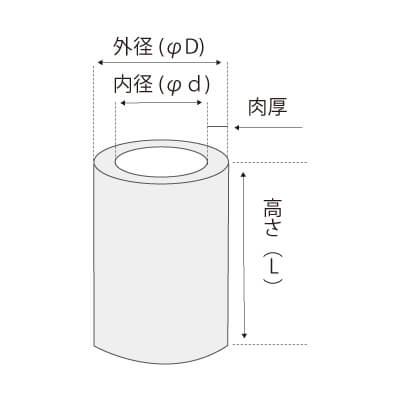

■ PTFE Pipe

|

|

|||||||||||||||||||||||||||||||

*1 Height can be adjusted from a minimum of 50mm to a maximum of 150mm (however, for heights of 101mm or more, the wall thickness must be 10mm or more).

*2 We also stock special sizes and shapes (square, ball, etc.) other than those listed above. Please contact us for details.

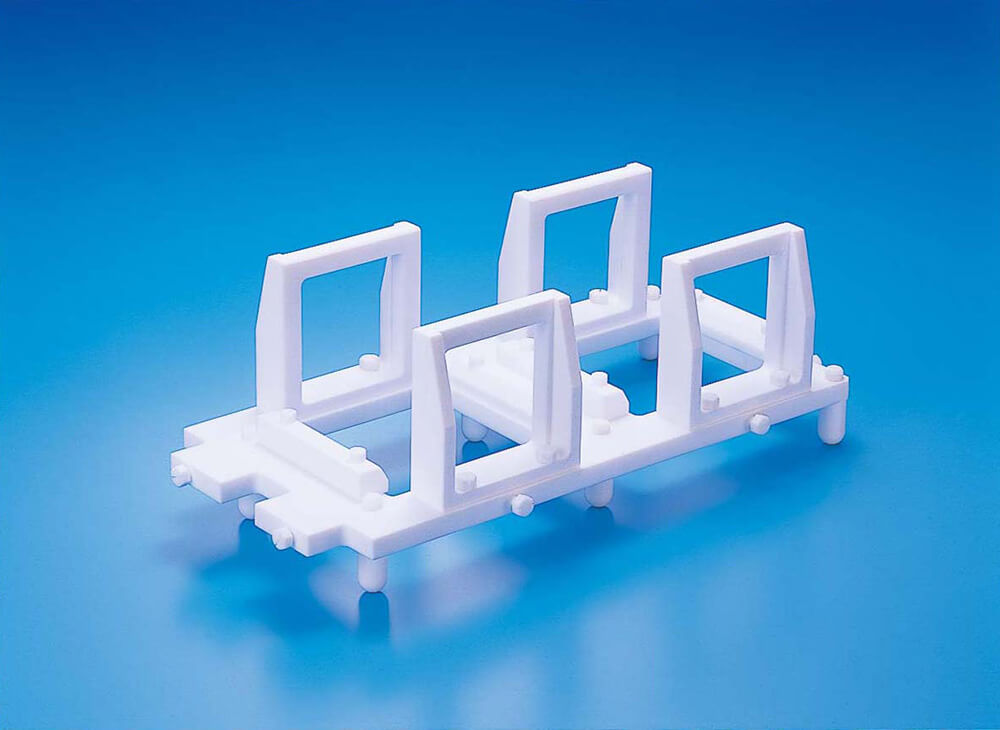

Compression Molded Products

ball

Ball seats and packing

Bellows

Piston rings and bearings