Polyimide adhesive tape is an adhesive tape that uses a polyimide film as a base material and has adhesive applied to one or both sides.As an adhesive tape that can be used in high temperature environments up to 250℃, it is used in the reflow process for mounting electronic devices and as heat-resistant masking.

This article explains the characteristics and uses of polyimide adhesive tape.

table of contents

-What is polyimide adhesive tape?

・Characteristics of polyimide adhesive tape (advantages and disadvantages)

・Main uses of polyimide adhesive tape

・Introduction of polyimide adhesive tape

·summary

What is polyimide adhesive tape?

Polyimide, which is used in polyimide adhesive tape, is a type of plastic classified as a super engineering plastic, and has imide bonds in the main chain of its molecular structure. It has the highest level of heat resistance and dimensional stability among all plastics.

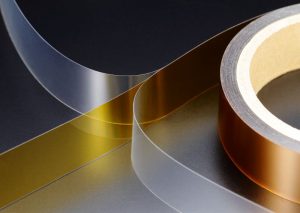

Polyimide adhesive tape is a brown translucent adhesive tape made by applying adhesive to one or both sides of this polyimide film.Because of its excellent heat resistance and dimensional stability, it is often used in the reflow process of electronic equipment parts in high-temperature environments and for heat-resistant masking purposes.

Characteristics of polyimide adhesive tape (advantages and disadvantages)

As mentioned above, polyimide has excellent heat resistance, dimensional stability, and Insulation properties. We will explain the advantages and disadvantages of adhesive tapes that utilize these polyimide characteristics.

Benefits

・Excellent heat resistance

The maximum operating temperature for polyimide alone is over 400 °C, making it one of the most heat resistance plastics.

Since polyimide adhesive tape is coated with an adhesive, the maximum operating temperature is lower than when the tape is used alone, but it is generally set at 250 °C.

-Excellent dimensional stability

Polyimide has excellent dimensional stability among plastics. Some plastics expand and contract due to sudden changes in temperature, but polyimide has a small linear expansion coefficient due to temperature changes and can maintain its dimensions even when used in high-temperature environments, so peeling and shifting can be prevented after application of polyimide adhesive tape.

-Excellent electric insulation

Polyimide also has excellent electric insulation and is used as an insulating base material for electronic circuits. Compared to other general-purpose resins, its electrical properties are stable over a wide temperature range.

Disadvantages

·Price is high

Compared to other plastics, it has excellent heat resistance, but is more difficult to process than general-purpose resins, making it a costly material.

Main applications of polyimide adhesive tape

Polyimide adhesive tape takes advantage of the characteristics of polyimide and is used in applications that require heat resistance, dimensional stability, and Insulation. It is used to protect and fix components in the reflow process, where intense temperature changes occur in high-temperature environments. It can also be used to bond components together in high-temperature environments.

Introduction of polyimide adhesive tape

Polyimide adhesive tape is widely used in electronic and electrical equipment due to its excellent heat resistance, dimensional stability, and electric insulation. We handle the following polyimide adhesive tapes. We can also make suggestions for specific applications, so please feel free to contact us.

■ API-114A FR (single-sided adhesive type)

This is a high heat resistant adhesive tape with a polyimide film base and a silicone adhesive applied to one side. It is suitable for applications that require heat resistance and electrical insulation. Since it is adhesive on one side, it can be used to mask and protect components during reflow processes in high temperature environments. The maximum operating temperature is 250 °C.

■ API-214A (double-sided adhesive type)

This is a highly heat-resistant adhesive tape with a polyimide film base and silicone adhesive applied to both sides. It is a thin, double-sided tape, so it is recommended for bonding parts in high-temperature environments. The maximum operating temperature is 250 °C.

■ API-214AE (One side strong adhesive, one side weak adhesive)

This is a highly heat-resistant adhesive tape with a polyimide film base and silicone adhesive applied to both sides. One side is lightly adhesive, so it is recommended for temporary fixing and holding of circuit boards during the reflow process. The maximum operating temperature is 250 °C.

Summary

Polyimide is a super engineering plastic that is characterized by its excellent heat resistance and dimensional stability. Therefore, polyimide adhesive tape that uses this polyimide can be used as insulation or heat-resistant masking in temperature environments below 250°C. We carry polyimide tapes that are recommended for fixing parts in the reflow process and for heat-resistant masking, so please feel free to contact us.