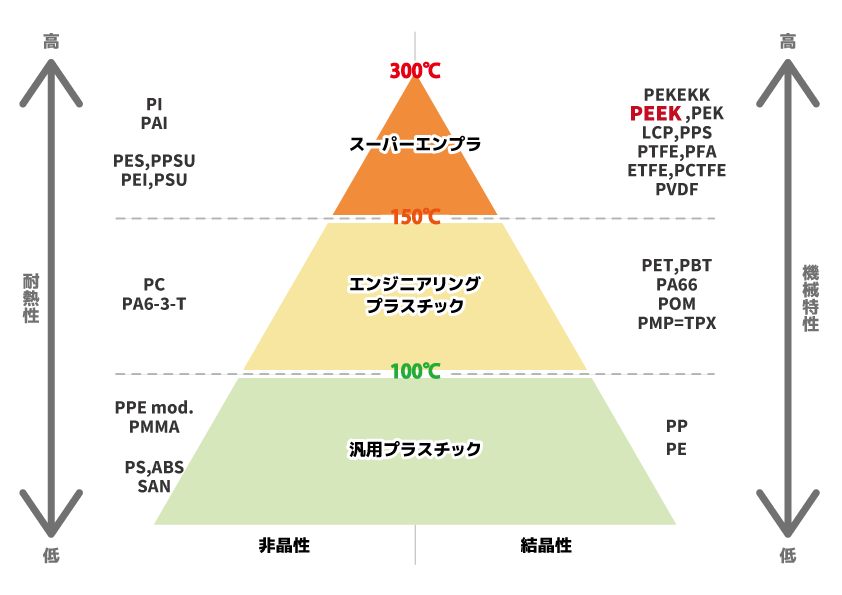

PEEK is a type of plastic classified as a super engineering plastic.

PEEK has excellent physical properties, is heat resistant, chemically stable, and mechanically tough. Therefore, it is used in various industrial fields, and is widely used in medical devices, aerospace industry, automotive industry, chemical industry, etc. In this article, we will explain the characteristics and applications of PEEK.

table of contents

・What is PEEK?

・Characteristics of PEEK (advantages and disadvantages)

・Types of PEEK

・Main uses of PEEK

・Introduction of PEEK products

·summary

What is PEEK?

PEEK is an abbreviation for Poly Ether Ether Ketone, a type of plastic classified as a super engineering plastic. It is called PEEK after the initials of its official name.

PEEK is a type of polymer known as aromatic polyether ketone (PAEK), which is classified as a thermoplastic resin.

The PAEK polymer group is composed of aryl, ether, and ketone groups, and the type and properties of the resin vary depending on the combination and arrangement of these groups. PEEK has a structure bonded by ether and ketone groups.

It has excellent heat resistance, chemical resistance, hot water resistance, flame retardancy, mechanical properties, and electrical properties, and is used in a variety of industrial fields, including medical equipment, the aerospace industry, the automotive industry, and the chemical industry.

Characteristics of PEEK (Advantages and Disadvantages)

PEEK has the following characteristics. Here, we will explain each characteristic and its advantages and disadvantages.

Benefits

・Excellent heat resistance

PEEK has excellent heat resistance among super engineering plastics. Its continuous use temperature is said to be around 260 °C, and its melting point is extremely high at 343 °C.

In addition, PEEK resin is resistant to hot water and steam, making it possible to sterilize it with steam.

-High mechanical characteristics

PEEK has excellent tensile strength and impact resistance even in high temperature environments.

Strength grades can also be increased by adding glass or carbon fibers.

・Excellent chemical resistance

PEEK has excellent chemical resistance. It is resistant to most acids and alkalis, but it is corroded by concentrated sulfuric acid, so care must be taken.

Another feature of PEEK is that it is resistant to these chemicals even in high temperature environments.

・Food safety is recognized

PEEK meets standards such as Japan's Food Sanitation Act and the U.S. FDA (Food and Drug Administration), and can be used for food contact applications.

・Excellent flame retardancy

One of the features of PEEK is that it is a flame-retardant material that produces very little smoke or toxic gases when burned.

Disadvantages

・Due to its extremely high strength, cutting and machining is difficult.

PEEK is characterized by its high mechanical strength, but one of its disadvantages is that it is difficult to machine or cut.

・High cost

PEEK is a resin that is expensive to produce and difficult to manufacture, so the cost is a burden.

Types of PEEK

There are various grades of PEEK. What is generally called "PEEK" is the basic grade. Here we will introduce the other grades.

・ Sliding grade

Basic grade with carbon fiber, graphite, PTFE Filled with this, it is a grade with excellent Lowest friction.

It has better Lowest friction and wear resistance than the basic grade.

It is used in products with sliding purposes such as bearings.

・ Glass fiber reinforced grade

It has better rigidity, dimensional stability, and creep resistance than the basic grade. It is used in places where static loads are applied.

・ Conductive Grade

By filling the basic grade with carbon fiber, it can be made conductive. It is used in places where static electricity and dust are undesirable.

Main applications of PEEK

Due to its excellent mechanical characteristics, PEEK is used in medical devices, the aerospace industry, the automotive industry, the chemical industry, etc. Because of these characteristics, it is also used as a substitute for metals for the purpose of reducing weight and improving performance.

In the medical field, PEEK is used in injection needles, implants, dentures, and more because it is non-toxic, inert, and highly biocompatible in the body.

Introduction of PEEK products

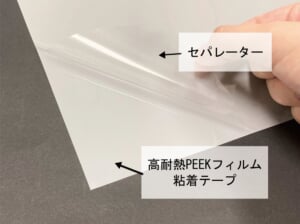

PEEK is used for a variety of purposes, but it can also be used as adhesive tape in addition to machine parts. When used as an adhesive tape, it can partially impart the properties of PEEK. We handle PEEK adhesive tape. Please feel free to contact us.

▼PEEK adhesive tape (developed product)

・ High heat resistant PEEK film adhesive tape "xACH-5102"

This is a highly functional adhesive tape with a silicone adhesive applied to one side of a highly heat-resistant PEEK film. In addition to the high heat resistance of the PEEK film, it also has high Insulation and low water absorption.

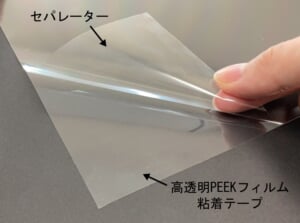

・ High heat-resistant transparent PEEK film adhesive tape for reflow soldering "xACH-5101"

This adhesive tape has a highly transparent PEEK film coated on one side with a mildly adhesive, highly heat-resistant silicone adhesive. In addition to the high heat resistance of the PEEK film, it is highly transparent, allowing for reflow and appearance inspection after masking.

Summary

PEEK is one of the super engineering plastics with extremely excellent characteristics.

Although it has the disadvantage of being difficult to cut, it has excellent heat resistance, chemical resistance, hot water resistance, flame retardancy, mechanical properties, and electrical properties, and can be used in many industries.